Built for Real Manufacturing.

Not Hypothetical AI.

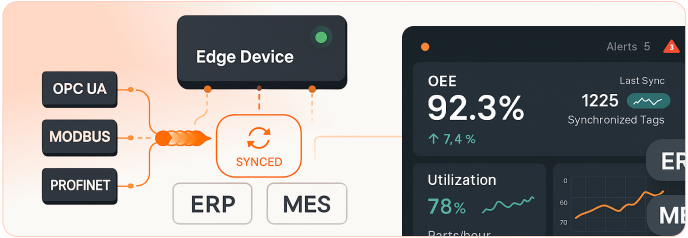

Direct Machine Layer

Integration

We integrate seamlessly with your PLCs, Robots, Sensors, and SCADA systems — no middleware, no complexity.

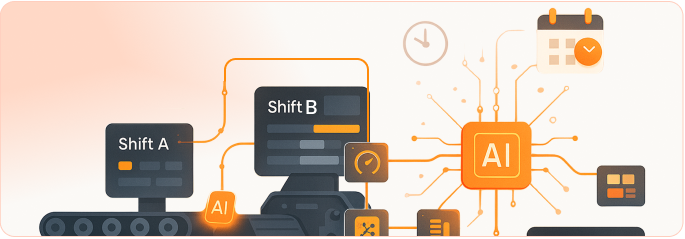

AI-Driven Scheduling & Decisioning

Works with Your ERP/MES

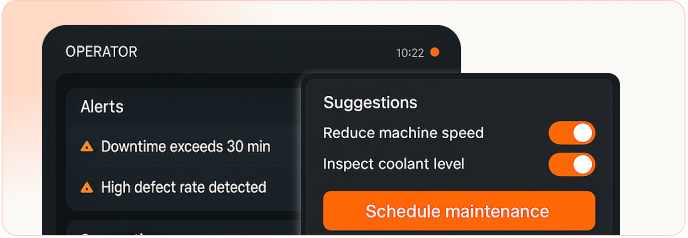

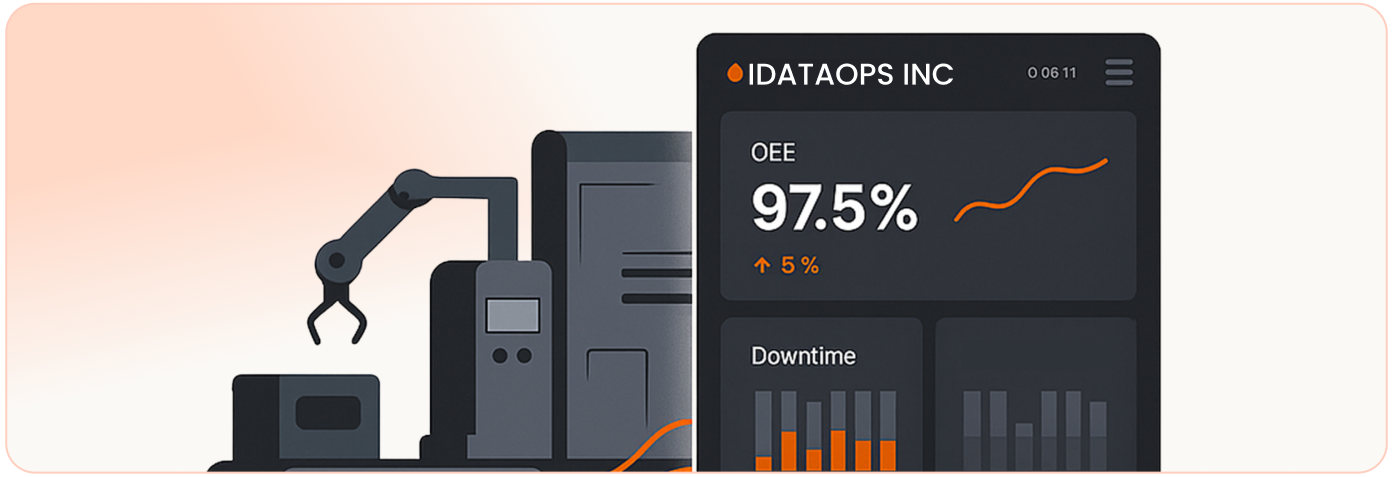

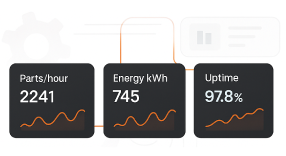

Real-Time Operational Visibility

Track everything from part counts to energy consumption — in real time, across your entire production process.

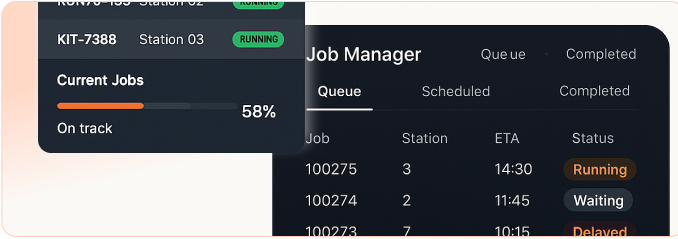

Closed-Loop Intelligence

iDataOps creates a continuous feedback loop between job progress, operator actions, equipment performance, and material usage.

Start Where You Need. Scale

When You’re Ready.

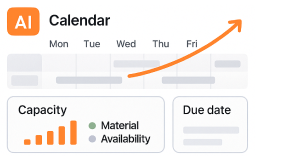

AI Scheduler

Automatically adjust schedules based on live capacity, equipment availability, and material status.

Try it ![]()

Machine + ERP Integrator

Seamlessly integrate machine data with your ERP system for smarter decisions.

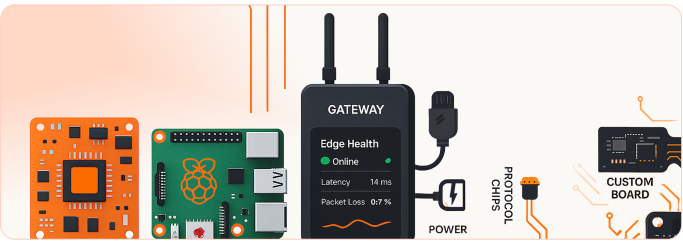

Edge Devices

Deployable on platforms like ADE9000, Raspberry Pi 5, or custom boards for edge data collection.

Purposeful AI. Trained in Real Machine Data.

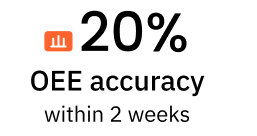

AI Scheduling Based on Live Capacity

Real-time adjustments to production schedules based on machine availability, labor, and material.

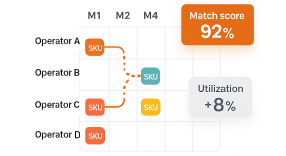

Operator-Machine-Product Matching

Automatically match operators with the right machines and tasks for optimal efficiency.

Material Consumption Forecasting

Leverage AI to predict material usage and avoid shortages or overages.

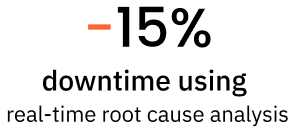

Downtime Prediction & Root Cause Tracing

Prevent downtime before it happens and drill down into root causes with AI-powered analysis.

Proven at Plant Floor. Trusted by Leaders.

From control rooms to C-suites, iDataOps delivers measurable transformation.

iDataOps user-friendly interface and advanced features have made significant reduction in production to me and an increase in quality of our products.

Pete Mazik

Operations Head

iDataOps' advanced analytics and real-time onitoring have given us unprecedented control over our production process.

Grant Branch III

CEO

With iDataOps, we unified 40 + machine feeds across lines in under a month gaining a true factory wide view of performance.

Josh Washington

Head of Digital

Transformation

How It Works

From Machine Signal to Real-Time Intelligence

Works with major protocols and platforms like

Let’s identify your first use case.

We’ll connect, collect, and show value — before any contract.