PRODUCTION

MONITORING

Overcome downtime challenges by tracking machine operations in real-time, utilizing advanced OEE, and enhance overall operational efficiency.

iDataOps Features

Advanced OEE

- Chart for machine uptime and downtime and calculate the Overall Equipment Effectiveness (OEE).

- Conduct a thorough OEE analysis, which can be viewed over various time frames, including months, days, hours, and even down to 60-minute intervals.

- Provides real-time data on equipment performance, allowing for immediate intervention and adjustments to prevent issues from escalating.

- Compare the performance of different equipment or production lines, enabling management to focus on areas that require the most attention and investment.

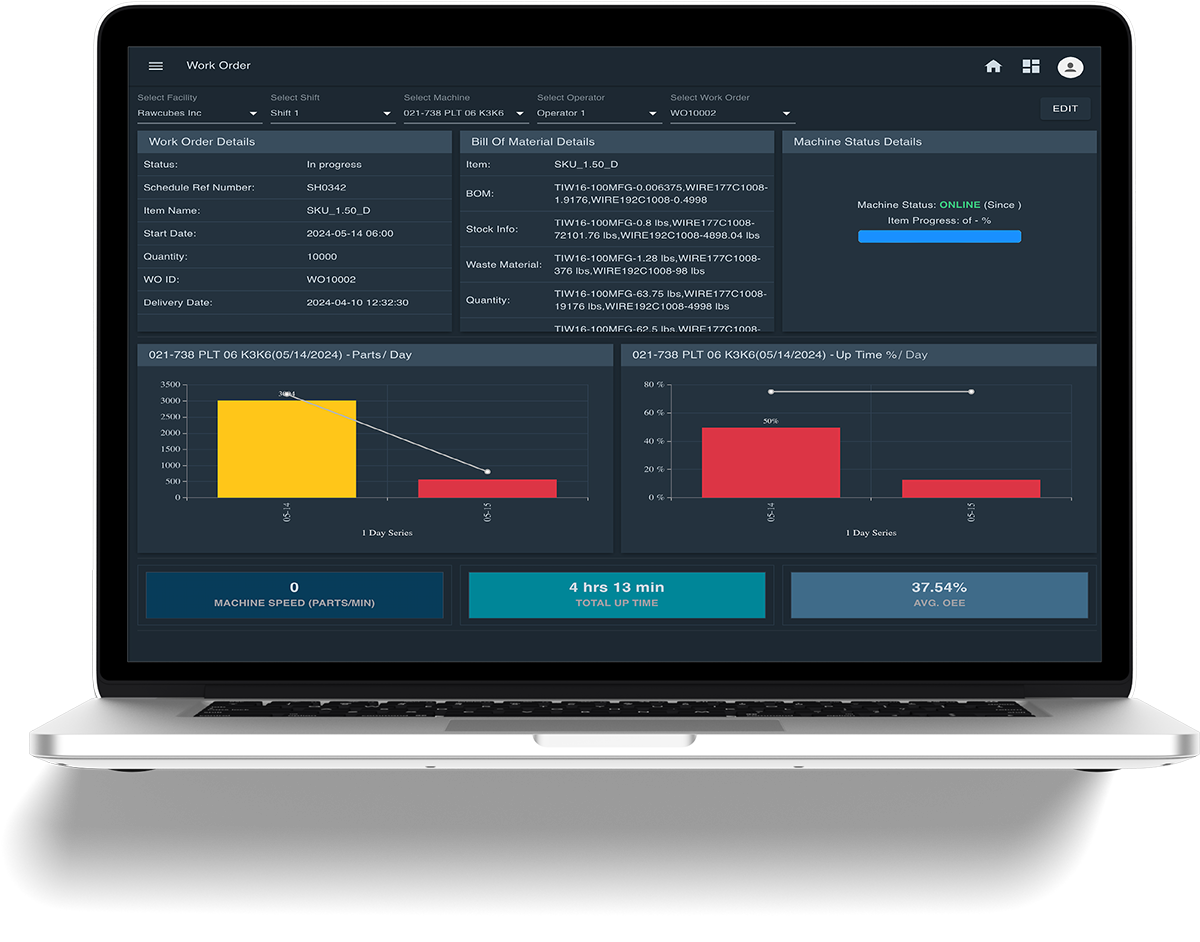

Work Order Management

- Integrate with existing ERP system and the work order management system for accurate data tracking, analytics, and utilization.

- Conduct in-depth analyses for specific work orders, determining factors such as OEE and work order variability compared to planned time.

- We can track production throughput, OEE, and daily throughput targets at the work order level to enhance decision-making.

- Production teams can swiftly identify and keep track of any anomalies or downtimes.

- If any irregularities occur during the day, assess whether there was downtime or any other anomalies by examining work orders.

Material Management

- An extensive stock availability dashboard that provides information on the inventory status at various facility locations.

- Comprehensive data reveals not only low stock levels and overstock situations but also items in need of reordering, the aging of stock, and the average lead time for restocking.

- The smooth integration of supplier ERP system data promotes efficient restocking processes, optimizes inventory and minimizes disruptions during periods of low stock availability.

Reports and Dashboards

- Varied parameters and filters are available to narrow down data by company, facility, last service record, and service location, facilitating precise data retrieval.

- The system empowers users to generate comprehensive reports for each piece of equipment, ensuring that service reminders remain up-to-date.

- These reports offer a holistic view of the equipment's maintenance history, streamlining the management and upkeep of equipment maintenance activities.