REAL-TIME

INSIGHT

Optimize operational efficiency and minimize costly downtime with predictive maintenance, advanced OEE (Overall Equipment Effectiveness), and seamless data integration.

iDataOps Features

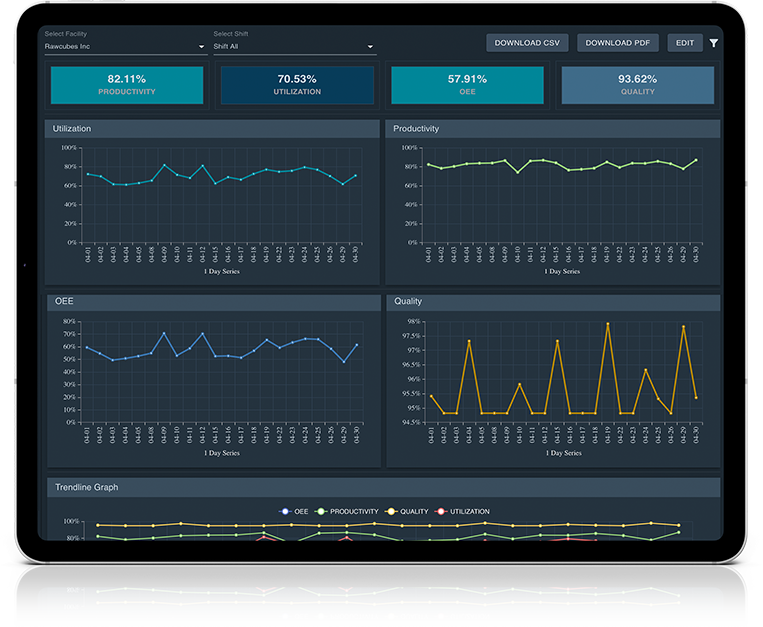

Centralized Command Center

- Unified dashboard for real-time monitoring of machinery, production processes, productivity, and resource utilization.

- View alerts and notifications for facility-wide operations.

- Factory and department-specific views, organized by production line.

- Efficiently manage equipment by operator, shift, group, and machine name.

- Machine efficiency directly correlates to quality, impacting scrap rates and overall production outcomes.

Performance Monitoring

- Leverage historical and real-time data to accurately forecast performance trends.

- Proactively schedule and optimize resource allocation to increase efficiency and reduce production risks.

- Empower your team to make data-driven decisions for timely delivery and higher production output.

- Optimize production processes by monitoring asset conditions and identifying improvement opportunities.

Predictive Maintenance

- Utilize AI & ML algorithms to make predictions.

- Predictive Remaining useful life (RUL) and mean time to failure (MTTF).

- Prioritize maintenance or replacement efforts on components with shorter RULs, ensuring the most critical assets are addressed first.

- Support through data scientist to uncover custom opportunities.

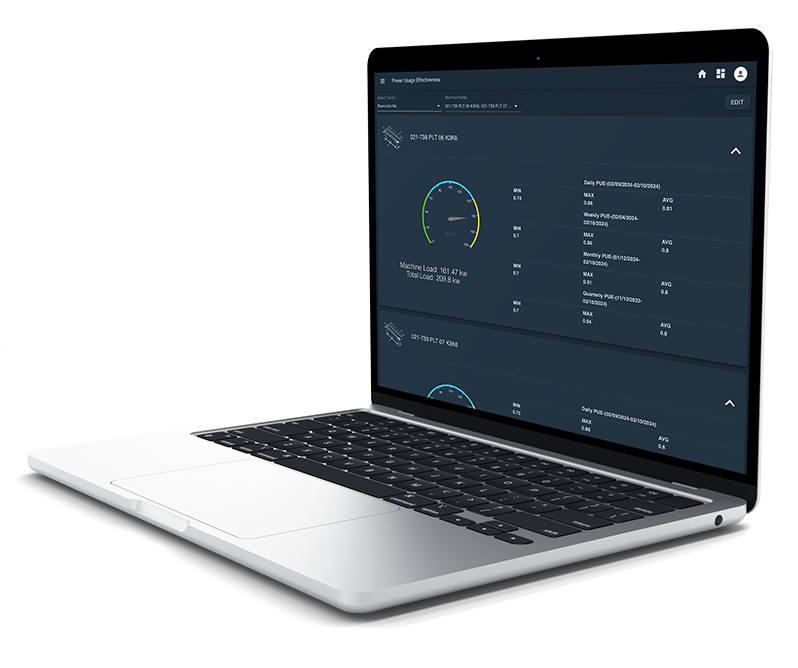

Power Usage Effectiveness

- Display of the machine's monthly, weekly, and daily load distribution in showing peak usage times and idle periods.

- Leverage a breakdown of energy consumption for the machines, to pinpoint which equipment may need maintenance.

- Real-time alerts for significant load variances, enabling maintenance teams to investigate, rectify issues and help in maintaining ESG levels.

Condition Monitoring

- Monitor equipment performance and analyze data, to identify when machines are experiencing wear and tear, and overheating for proactive replacement before they fail and cause unexpected downtime.

- Excessive vibration accelerates equipment wear and early failure. Our predictive maintenance tool monitors vibrations, spotting irregular patterns for early detection and prompt corrective action.

- Streamline the process of monitoring equipment and utilize real-time insights for improved decision-making for improved production.